Hidden fasteners provide a reliable option to overcome the pitfalls associated with traditional fastening through the boards.

Hidden Fastening Systems Products

Pro Biscuit

5 MM and 3 MM Gap options

Wood and metal joist screws

Used with Deck-Max pro timber

Tools & Accessories

Decking clamps, glue & much more

Making decking project easier

Large range of tools & accessories

Deck-Max Original Kits

This is decking kit is perfect for 4 to 6 square metres (SQM) of decking depending on the width of the board. The kit comes with Self Drilling Metal Screws for high quality corrosion resistance No Nails – No Screws in the surface.

Shop

Email us at [email protected] to order

Showing all 8 results

-

DM 4031 - Original # 5 - Wood Frame Kit 304SS 4 mm

$128.00 Add to cart -

DM 4093 – Original # 20 - Wood Frame Kit 304SS 4 mm

$434.00 Add to cart -

DM 4452 – TRADIE Original # 5 - 304SS Kit 4 mm

$79.20 Add to cart -

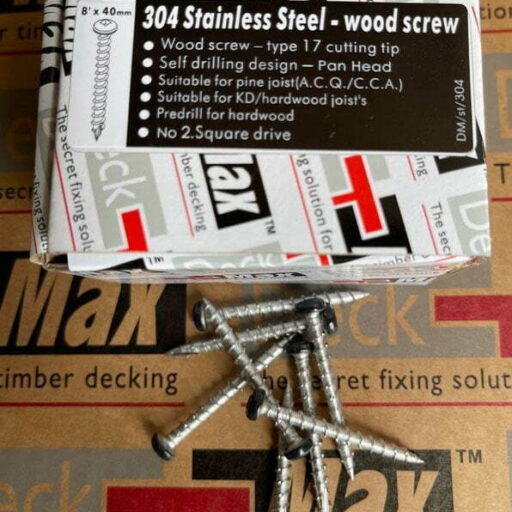

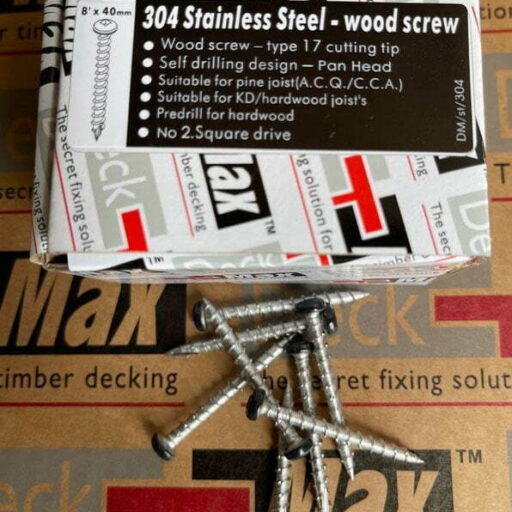

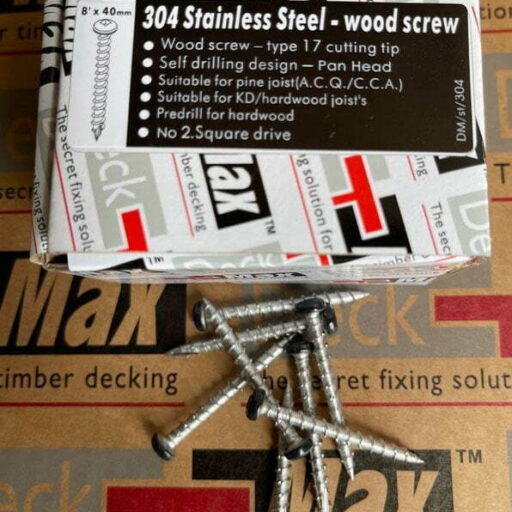

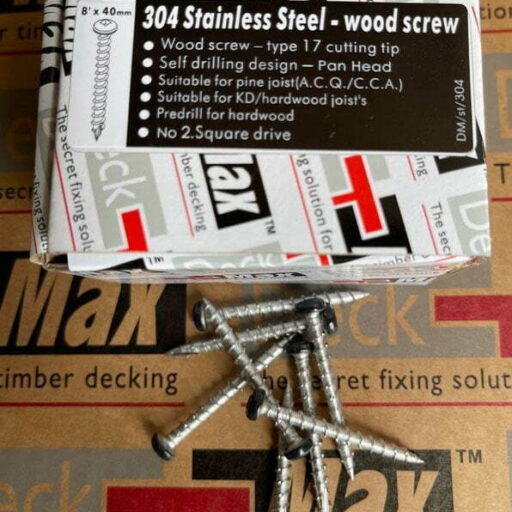

DM 4123 Stainless Steel Screw - Pan Head / self drilling wood screw

$33.00 Add to cart -

DM 4024 – Original # 5 - SD Metal Frame Kit 4mm

$128.00 Add to cart -

DM 4086 – Original # 20 - SD Metal Frame Kit 4mm

$434.00 Add to cart -

DM 4455 – TRADIE Original # 5 - SD Metal Kit 4 mm

$79.20 Add to cart -

DM 4116 Self Drilling Metal Screws

$33.00 Add to cart

Shop

Email us at [email protected] to order

Showing all 14 results

-

DM 4666 - EM Pro 5mm - # 20 Kit 304SS

$434.00 Add to cart -

DM 4635 - EM Pro 5mm - # 5 Kit 304SS

$128.00 Add to cart -

DM 4390 - EM Pro 3mm - # 20 Kit 304SS

$434.00 Add to cart -

DM 4338 - EM Pro 3mm - # 5 Kit 304SS

$128.00 Add to cart -

DM 4450 - TRADIE Pro # 5 - 304SS Kit 3 mm

$79.20 Add to cart -

DM 4451 – TRADIE Pro # 5 - 304SS Kit 5 mm

$79.20 Add to cart -

DM 4659 - EM Pro 5mm - # 20 Kit Self drilling metal screws

$434.00 Add to cart -

DM 4628 - EM Pro 5mm - # 5 Kit Self drilling metal screws

$128.00 Add to cart -

DM 4383 - EM Pro 3mm - # 20 Kit Self drilling metal screws

$434.00 Add to cart -

DM 4321 - EM Pro 3mm - # 5 Kit - Self drilling metal screws

$128.00 Add to cart -

DM 4454 – TRADIE Pro # 5 - SD Metal Kit 5 mm

$79.20 Add to cart -

DM 4453 – TRADIE Pro # 5 - SD Metal Kit 3 mm

$79.20 Add to cart -

DM 4123 Stainless Steel Screw - Pan Head / self drilling wood screw

$33.00 Add to cart -

DM 4116 Self Drilling Metal Screws

$33.00 Add to cart

Deck-Max Pro Kits

The Deck-Max Pro biscuit system with End matching is specifically a one stop package that includes this superior biscuit system.

Decking size can vary from 90mm wide to 147mm wide and 19mm to 24mm thick. This biscuit can only be purchased from Deck-Max (pre grooved both side and end matched both ends.) ends are also under cut.

End Matching Decking

A common issue with traditional decking, is the waste created by having to start and finish each length on a joist of the sub frame. You now have a better option, in the form of End Match. Another Deck-Max innovation that allows you to join boards at any point on the sub-frame.

This provides you with several advantages, enabling each length of timber to be used completely more often, slashing waste by 80% down to about 2%.

Additionally, you also save about 30% on installation time by eliminating much of the cutting traditionally needed to get boards to the right length.

Shop

Email us at [email protected] to order

Showing all 10 results

-

DM 4666 - EM Pro 5mm - # 20 Kit 304SS

$434.00 Add to cart -

DM 4635 - EM Pro 5mm - # 5 Kit 304SS

$128.00 Add to cart -

DM 4390 - EM Pro 3mm - # 20 Kit 304SS

$434.00 Add to cart -

DM 4338 - EM Pro 3mm - # 5 Kit 304SS

$128.00 Add to cart -

DM 4659 - EM Pro 5mm - # 20 Kit Self drilling metal screws

$434.00 Add to cart -

DM 4628 - EM Pro 5mm - # 5 Kit Self drilling metal screws

$128.00 Add to cart -

DM 4383 - EM Pro 3mm - # 20 Kit Self drilling metal screws

$434.00 Add to cart -

DM 4321 - EM Pro 3mm - # 5 Kit - Self drilling metal screws

$128.00 Add to cart -

DM 4123 Stainless Steel Screw - Pan Head / self drilling wood screw

$33.00 Add to cart -

DM 4116 Self Drilling Metal Screws

$33.00 Add to cart

Shop

Email us at [email protected] to order

Showing all 13 results

-

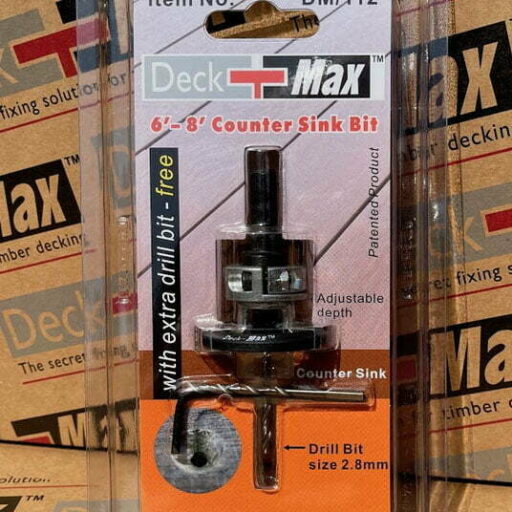

DM 4253 CounterBore Tool

$62.00 Add to cart -

DM 4123 Stainless Steel Screw - Pan Head / self drilling wood screw

$33.00 Add to cart -

DM 4277 Wood Plug Kit

$38.00 Add to cart -

DM 4147 Combo Pack - 50mm #2 sq. drive + 100mm x 3mm drill bit

$17.00 Add to cart -

DM J10 Butt Joiner

$10.00 Add to cart -

DM 4116 Self Drilling Metal Screws

$33.00 Add to cart -

DM 4260 CounterSink Tool

$53.00 Add to cart -

DM 4154 Combo Pack - 100mm x # 2 sq. Drive Bits

$11.00 Add to cart -

DM 2010 Bostik Ultraset 300ml - Acoustic Membrane

$14.30 Add to cart -

DM 4004 450mm Combo Decking Clamp

$60.00 Read more -

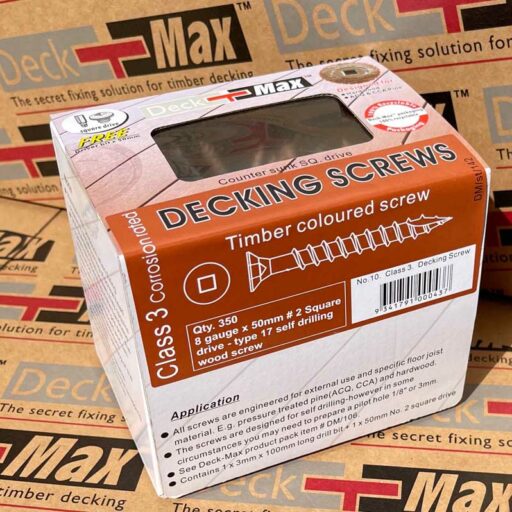

DM 4437 A brown screws (Class 3 | # 2 sq. drive| Type 17 | 50mm) - Pack of 50

$11.00 Add to cart -

DM 4280 Drill Bit Pack

$9.00 Add to cart -

DM 4437 brown screws (Class 3 | # 2 sq. drive| Type 17 | 50mm) - Pack of 350

$53.00 Read more

Tools & Accessories

One Stop Shop Solution – offering you a wide variety of materials, fixings, tools and accessories to suit all projects delivered anywhere in Australia.

When starting to decide on your deck having the right equipment and supply’s is a must. We have you covered!

Everything from Glue, Decking Clamps, Primer, Drive Bits. Counterbore Tools, Wood Plug Kits and more.

Deck-Max Butt Joiners

DM J10 Butt Joiner

$10.00

DM J10 Butt Joiner

Suitable For:

- Fixing/Joining mitred corners

- Joining end boards to framing boards

- Butt Joining ends on Joists (butt joints) – must join on joists unless using the end matched decking by Deck-Max.

- 15pcs/ pack

Note: This is not to be used for end matching or joining between joists

End match – hidden fastening that reduces waste

A common issue with traditional decking, is the waste created by having to start and finish each length on a joist of the sub frame. You now have a better option, in the form of End Match. Another Deck-Max innovation that allows you to join boards at any point on the sub-frame.

This provides you with several advantages, enabling each length of timber to be used completely more often, slashing waste by 80% down to about 2%. Additionally, you also save about 30% on installation time by eliminating much of the cutting traditionally needed to get boards to the right length.

Contact our

Decking Specialists Today!

Stunning Decks With Deck-Max Products